Airframe Control Ball Bearings

Airframe control ball bearings reduce friction and support high radial and axial loads, providing smooth, precise motion in flight control systems. These specialized bearings ensure dependable performance in demanding aerospace environments, making them absolutely critical for OEMs and maintenance teams seeking reliability, safety, and long-lasting durability.

Engineers use airframe control bearings in aircraft control linkages, actuators, and other flight control mechanisms where accuracy is essential. Their durability and load-handling capabilities also make them suitable for other high-performance applications requiring dependable motion control. We can lubricate these bearings with grease or oil, depending on the application, load capacity, speed, or temperature

Alpine Bearing carries aircraft needle bearings from Accurate, Carter, IJK, NHBB, NMB, RBC, and Schatz.

Key Features of Airframe Ball & Needle Roller Bearings

Airframe control ball bearings and needle roller bearings stand out for their strength-to-weight ratio, which supports even the most demanding aerospace applications. Specialized raceway finishes reduce friction and heat, substantially extending service life in these harsh conditions.

The ball bearings’ design ensures accurate movement of control surfaces, delivering the reliability that aircraft manufacturers and maintenance teams depend on.

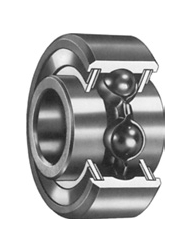

Single & Double Row Airframe Control Ball Bearings

Aircraft bearings are lightweight and safe for extreme environments. They are typically used to support high loads that spin at medium to low RPMs and are commonly oscillating.

Single Row

These bearings can take many forms, including single, double row, or thin-section ball bearings. Below are some of our single-row airframe control ball bearing options:

Double Row

However, double-row bearings are the way to go if you’re looking for increased load capacity and speed. We offer these in numerous types, as well:

Regardless of which you choose, both ball bearing options ensure dependable operation in precise flight systems.

Why Airframe Control Ball Bearings Are Essential in Aerospace Applications

Airframe control ball bearings play a critical role in ensuring the safety of aircraft systems. They work to maintain stable movement of control surfaces under high stress, allowing pilots to rely on a consistent response in flight.

The ball bearings’ ability to perform in extreme environments, combined with certification-backed quality, makes them indispensable for OEMs and maintenance teams across the aerospace industry.