Needle & Roller Bearings

As a leading needle and roller bearing distributor, Alpine Bearing provides components engineered for strength, precision, and reliability. These precision needle roller bearings use slim rollers to maximize load distribution while minimizing space requirements. Their proven performance makes them essential in aerospace and industrial applications where durability and efficiency drive success.

Engineers use lightweight needle bearings in aircraft controls, potentiometers, and joysticks where precision is essential. Their high load capacity makes them useful in farm and construction equipment as well. We can lubricate these bearings with grease or oil, depending on the application, load capacity, speed, or temperature.

Alpine Bearing carries aircraft needle bearings from Schaeffler, Accurate, and RBC.

Precision Needle Roller Bearings & Their Applications

As a precision needle roller bearings distributor, Alpine Bearing understands the importance of maintaining a compact profile for these parts, ensuring they’re ideal for assemblies with limited space.

Their design minimizes friction and wear, ensuring smooth performance over long service cycles. These bearings are widely used in aerospace flight systems, medical equipment, robotics, and industrial machinery that demand reliability and accuracy.

Needle Bearing Inch & Metric Options

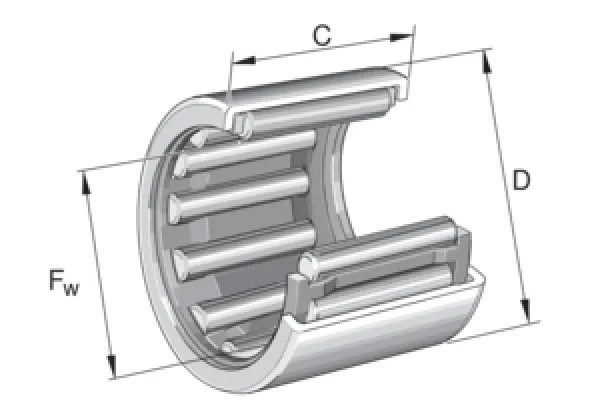

Needle and roller bearings differ from other ball bearings because of their long, thin, needle-like components which take the place of the balls in other bearings. The needles, longer than the width of the bearing, provide a more frictionless rolling mechanism and a larger surface area. That surface area means the bearings distribute weight better and can carry heavier loads.

These bearings, which are lightweight and safe for extreme environments, are typically used to support high loads that spin at medium to low RPMs and are commonly oscillating. They can take many forms, including single, double row, or thin-section ball bearings.

Choose from the following:

Key Features of Needle & Roller Bearings

OEMs and replacement buyers choose needle and roller bearings because of their specialized engineering and innovative features.

These include:

- Precision ground rollers for accurate load distribution and smooth operation

- Heat-treated components that withstand extreme temperatures and heavy cycling

- Lubrication options that extend bearing life in aerospace and industrial settings

- Inch and metric availability for seamless integration into global systems

- Manufactured to ISO and AS9100 quality standards for proven dependability

These features set precision needle roller bearings apart as trusted components in both aerospace applications and advanced industrial equipment.