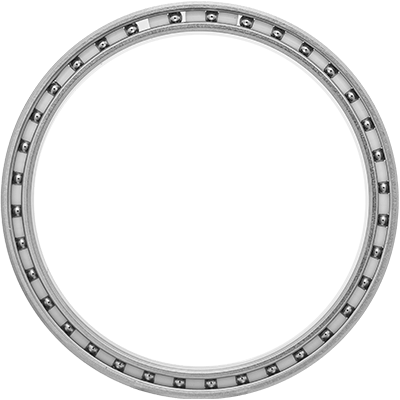

Torque Tube Bearings

Torque tube bearings deliver low friction, high accuracy, and exceptional torque control in compact assemblies. By distributing loads across a greater number of small-diameter balls, these bearings achieve smoother rotation and reduced startup resistance.

Available in both radial and angular contact configurations, they support lightweight, high-precision applications in aerospace systems, robotics, medical instruments, and advanced electronics.

Alpine Bearing is a trusted Torque tube bearing supplier, offering premium options from myonic, NHBB, NMB, and RBC.

Our Selection of Torque Tube Bearings

As a leading torque tube bearing supplier, we offer a focused range of tube bearing options to meet the needs of OEMs requiring ultra-slim profiles and consistent performance. Below, you can explore our inventory of radial and angular contact designs, available in multiple sizes and configurations.

Radial Ball Bearings

Torque tube series radial ball bearings work for shaft positioning and rotational accuracy in space-constrained systems. With outer diameters available up to six inches, these bearings offer stable, low-friction operation for even the most compact assemblies.

Common applications include aircraft instrumentation, robotics, missile guidance hardware, and advanced medical devices.

View our radial bearing options here:

Angular Contact Ball Bearings

Angular contact versions of torque tube bearings are crafted for combined radial and axial loads, providing precise alignment under dynamic operating conditions.

These bearings are commonly used in instrument systems where low torque and high positional accuracy are essential. Duplex preloaded matched sets are available to support zero clearance and enhanced rigidity for critical applications.

View our angular bearing selections here:

Functional Advantages of Torque Tube Bearings

Manufacturers craft torque tube bearings specifically for environments where space, weight, and precision are tightly controlled. Their unique construction supports performance in high-speed, low-friction systems, especially in aerospace and instrumentation, where even minor deviations can cause major issues.

Below are other key characteristics and advantages that torque tube bearings can bring to your applications:

- Low Starting and Running Torque: achieved through a high ball count and reduced ball diameter

- Compact, Low-Profile Design: ideal for tight spaces in electronics, actuators, and airborne systems

- Consistent Load Distribution: helps maintain accuracy under radial and axial forces

- Available in Duplex Preloaded Sets: for zero clearance and improved positioning control

- Optimized for Lightweight Assemblies: supports reduced mass without compromising strength

These features make torque tube bearings the preferred choice for engineers building high-precision systems where space and efficiency are non-negotiable.

Source Torque Tube Bearings With Confidence

Alpine Bearing is proud to be a trusted torque tube bearing supplier, always providing fast access to in-stock sizes and expert support for custom specs.Contact us to check availability, request a quote, or get help matching bearings to your application.Torque Tube Bearing FAQs

What industries rely on torque tube bearings?

Industries like aerospace, defense, robotics, medical equipment, and instrumentation systems widely rely on torque tube bearings. Their compact size and low-torque performance make them ideal for guidance systems, avionics, and other high-precision applications.

Are torque tube bearings available in stainless steel or other materials?

Yes, we offer these bearings in a variety of materials, including stainless steel and specialty alloys, depending on the application’s environmental and load requirements. Alpine’s experts can help source the right material configuration for your system.