Turbo Pump Bearings

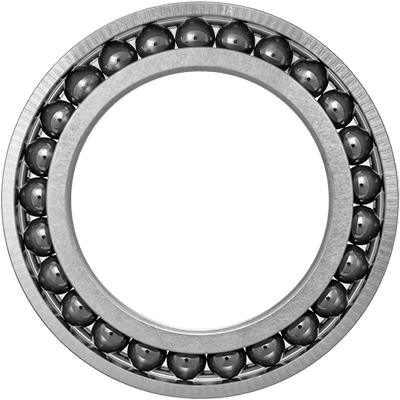

Turbomolecular pump bearings operate in extreme conditions, where precision and speed are absolutely everything. These specialized turbo pump bearings handle high rotational speeds, intense vacuum environments, and demanding thermal loads, all while maintaining smooth, quiet performance.

Alpine Bearing supplies a full range of turbomolecular pump bearings from trusted manufacturers like Barden and GRW, ensuring reliable operation for advanced vacuum systems and high-performance equipment.

Key Features & Performance Benefits of Turbo Pump Bearings

Turbo pump ball bearings use advanced materials and geometries to reduce vibration and maintain performance under extreme rotational speeds. Because of this, many OEMs rely on bearings for applications that require ultra-clean environments and virtually frictionless operation.

Our team selects each bearing type used in turbomolecular pumps to meet the specific demands of the system, whether that’s tight dimensional tolerances, low torque startup, or thermal stability.

By maintaining stable operation under thermal and mechanical stress, these high-performance bearings support consistent vacuum pressure and help protect critical components – such as rotor shafts, stator coils, or motor windings – from failure.

Mag-Lev Ball Bearings

Turbo pump magnetic levitation bearings are used to protect rotors in case of magnetic field failure. This type of bearing is for safety purposes only.Not finding your pump model or size listed? Alpine Bearing is constantly developing new sizes and values your input and questions. Please feel free to contact our turbo pump specialist at turbo@alpinebearing.com

Types of Turbomolecular Pump Bearings

Turbomolecular pumps rely on specialized bearing configurations to support different design requirements and operating conditions. The two most common options, turbo pump ball bearings and maglev turbo molecular pump bearings, each offer unique characteristics and safety functions, and knowing the difference is key to making the best choice for your operations.Turbo Pump Ball Bearings

Turbo pump ball bearings are the primary support system for most turbomolecular pump designs. They’re known for their precision and durability in continuous, high-speed rotating equipment. OEMs choose these ball bearings for their low torque, high load capacity, and stability in vacuum environments. Alpine Bearing works with leading manufacturers to supply high-performance replacement bearings specifically for turbo pump systems.

Maglev Turbo Molecular Pump Bearing

Maglev turbo molecular pump bearings serve as a backup in magnetically levitated systems, protecting the rotor in the rare event of magnetic field disruption.

Though they are not active during regular operation, these bearings play a critical role in preventing damage during shutdowns or system faults, ensuring the safety and longevity of advanced turbomolecular pump assemblies.

Industries & Applications for Turbomolecular Pump Bearings

Alpine Bearing proudly supplies turbomolecular pump bearings and maglev turbo molecular pump bearings for OEMS across a wide range of precision-driven industries, including:

- Semiconductor and Thin‑Film Deposition Systems

- Aerospace and Defense

- Medical and Laboratory Instrumentation

- Robotics and Automation Systems

- Machine Tool Repair and Vacuum Component Rebuilds

Each of these applications demands bearings with ultra-low contamination, thermal stability, and long service life. These are all performance characteristics that define Alpine’s turbo pump offering. Not finding your pump model or size listed? Alpine Bearing is constantly developing new sizes and values your input and questions. Please feel free to contact our turbo pump specialist at turbo@alpinebearing.com.

Ready to Order Turbomolecular Pump Bearings?

Whether you’re sourcing replacement turbo pump ball bearings or planning a new system with maglev turbo molecular pump bearings, Alpine delivers fast access to inventory and expert support. Talk to our specialists to request specs, confirm sizing, or get a quote that aligns with your specific vacuum system requirements.Turbo Pump Bearing FAQs

What materials are used in turbomolecular pump bearings?

Turbo pump bearings often use hybrid ceramic designs with stainless steel or high-grade alloys for the races and silicon nitride balls

Can you relubricate or refurbish turbo pump bearings?

Yes! Alpine offers cleanroom relubrication services for select turbomolecular pump bearings, using low-vapor-pressure lubricants compatible with vacuum applications. This service can extend bearing life and reduce downtime for OEM systems.

Do maglev turbo molecular pump bearings require regular maintenance?

Maglev bearings are non-contact and require minimal maintenance under normal conditions. However, auxiliary support bearings may still need inspection or replacement depending on system usage and load cycles.